I’m Marc…

I have always strived to grow, and learn more about developing disruptive technology.

As a 4th-year mechatronics engineering student at the University of British Columbia, I have had the opportunity to work on some of North America’s most efficient vehicles.

I worked at Apple, Tesla, and Unilia as a Mechanical Engineering Intern.

At Apple, I developed testing stations that were able to save $5M per year.

At Tesla, I designed a humanoid robot wrist and forearm.

At Unilia, I brought up multiple test stations and automated data analysis.

Let’s Meet

My Work Experience at UBC Supermileage

Powertrain Division lead - Apr 2020→present

Leading a division of 11 students, responsible for building the Internal Combustion Engine powertrain that won 2nd in North America (2229 mpg) in the Shell Eco-Marathon Americas and SAE Supermileage.

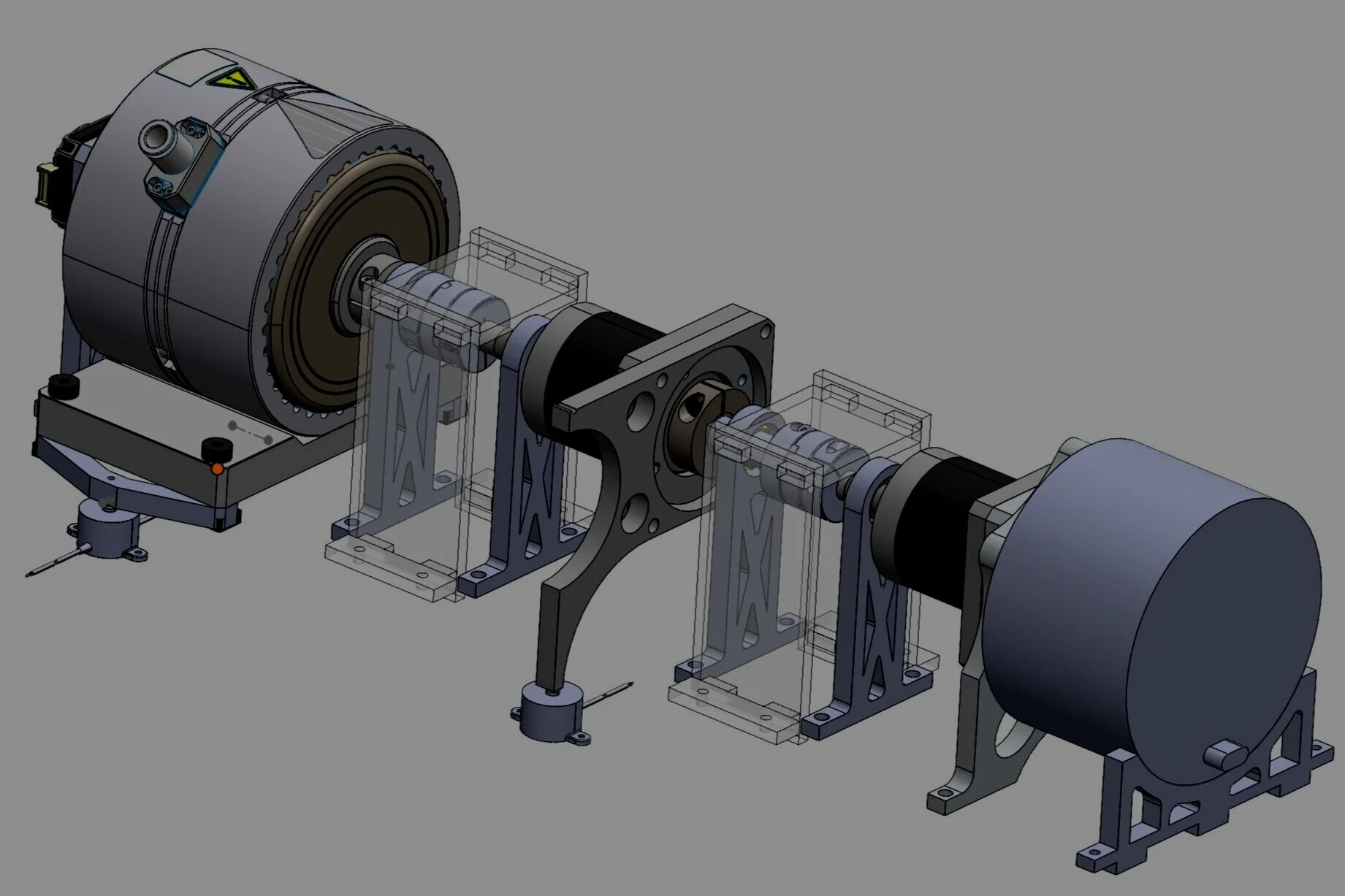

Orchestrated the development of a new electric powertrain for our prototype class vehicle that attempted to break the current record for the world's most efficient fuel cell vehicle.

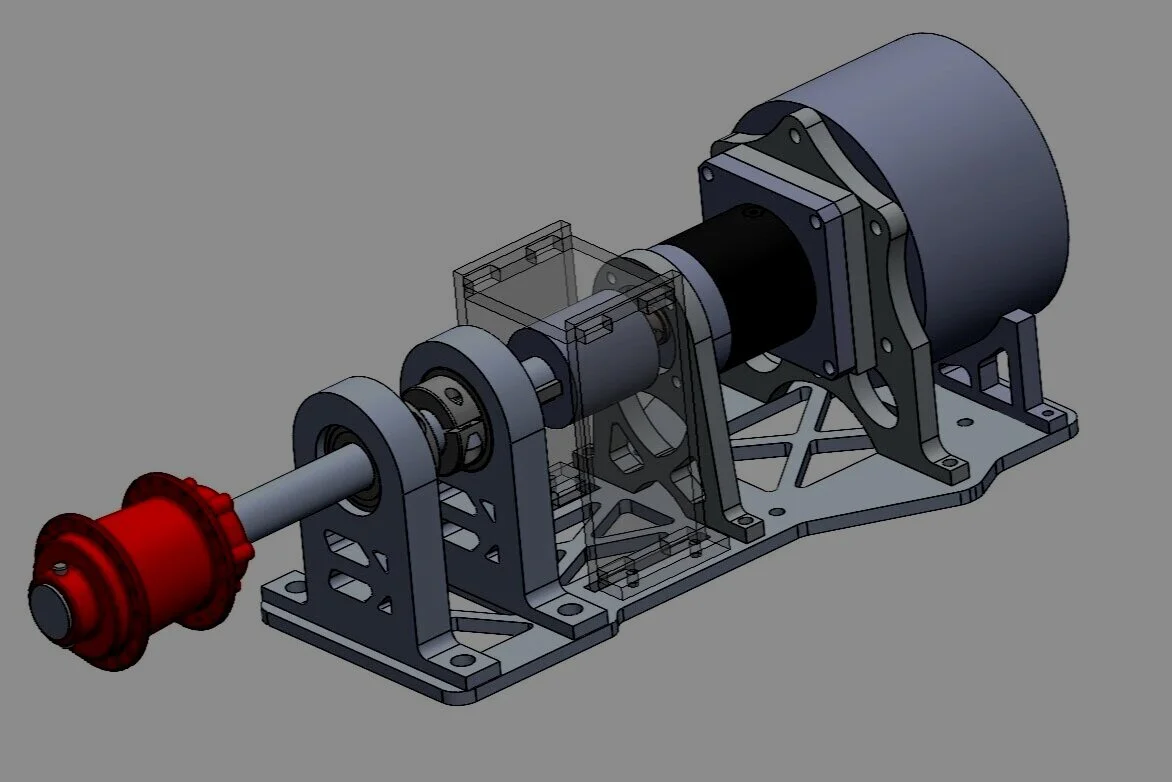

Designed and fabricated a dynamometer able to obtain and log powertrain performance at any RPM and torque combination.

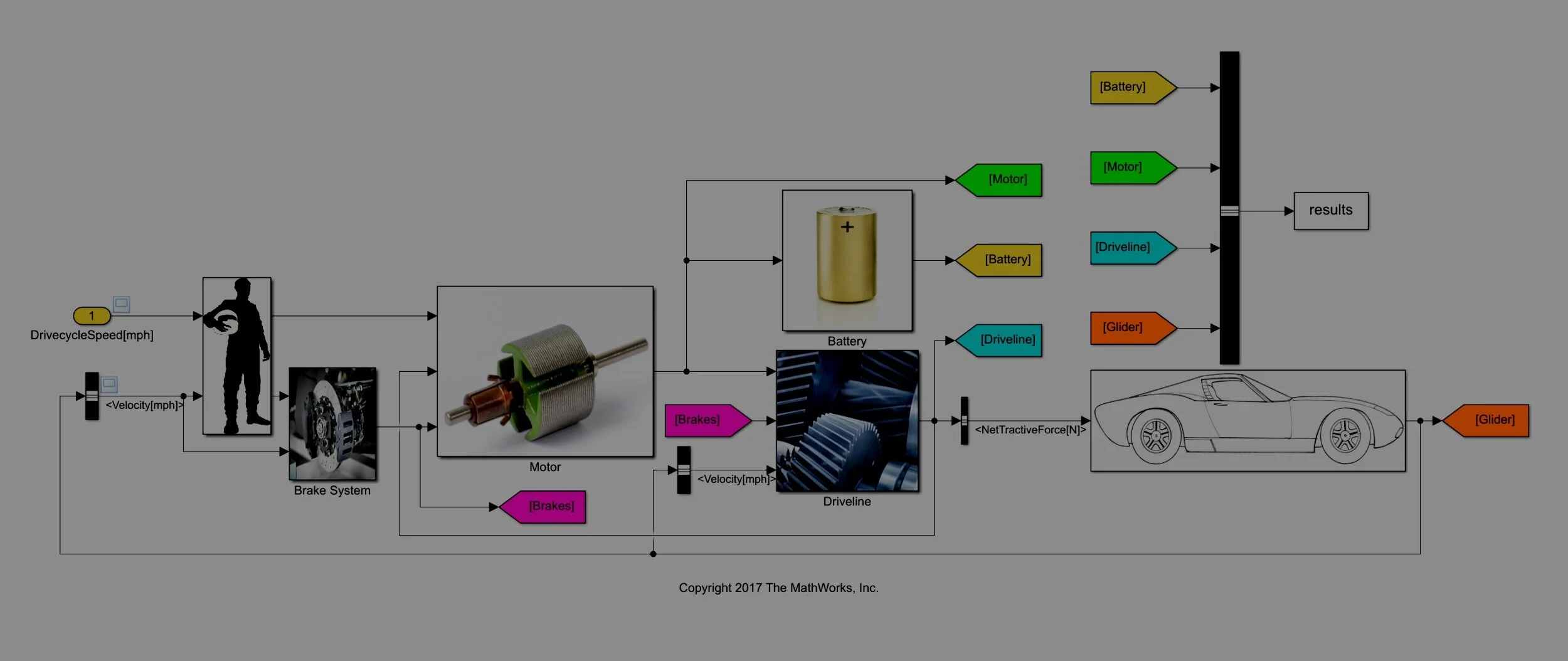

Developed a MATLAB simulation that predicts powertrain load, efficiency, speed on any track with 85% accuracy.

Powertrain Project Lead - Apr 2019→Apr 2020

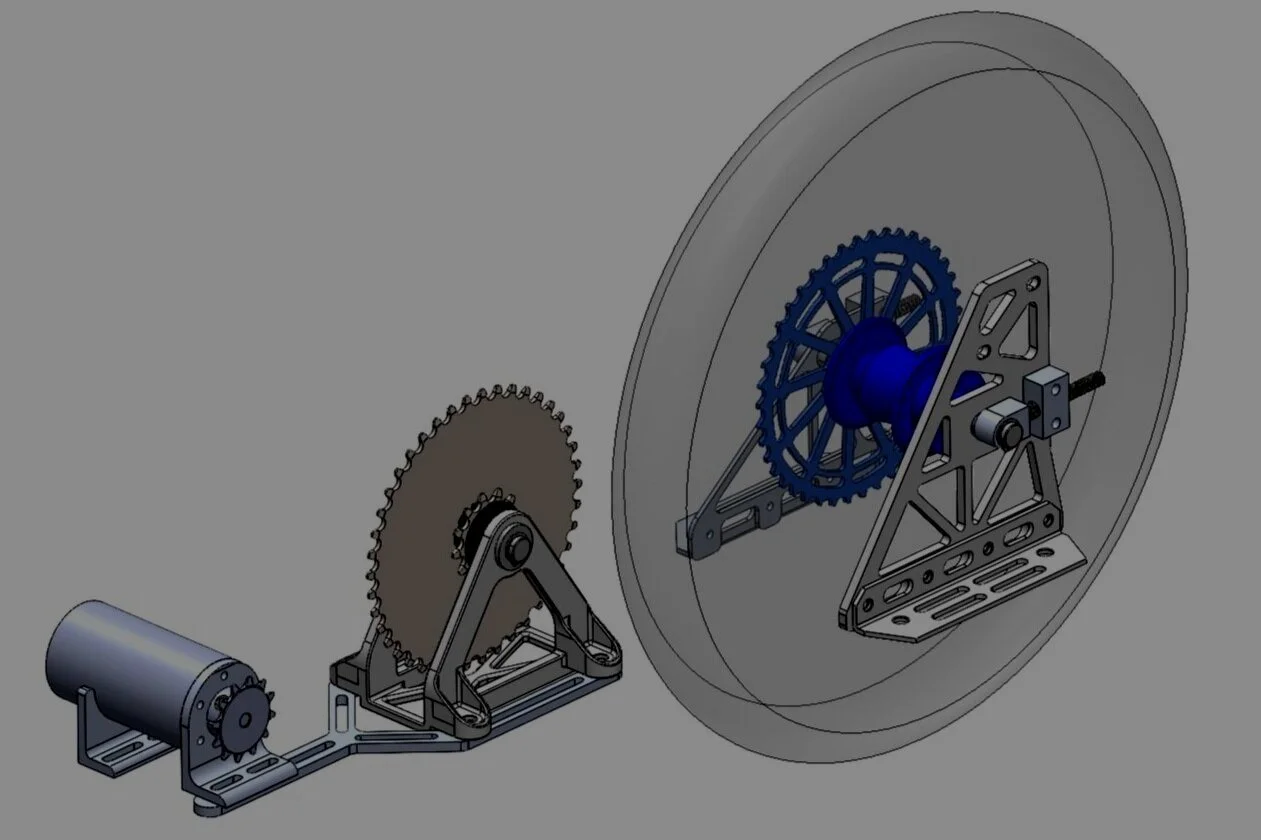

Machined and implemented a new electric powertrain for our Urban vehicle, reducing weight by 30% and increasing efficiency by 20%.

Redesigned 4 lightweight aluminum mounts by introducing topology optimization to the team's design process.

Identified and researched motor/gearbox combinations that minimize energy loss and satisfy power, speed, and motor controller constraints.

Powertrain General Member - Sep 2018→Apr 2019

Simplified throttle body assembly, reducing assembly time by 85%.

Designed and manufactured 2 gearbox mounts crucial for shaft alignment using the mill, bandsaw, water-jet cutter, and drill press.

Molded 2 lightweight composite guards using power tools and carbon fiber layups to ensure driver safety.

my Resume