Objective

Design a dyno that allows the Supermileage team to test any motor controller or powertrain component.

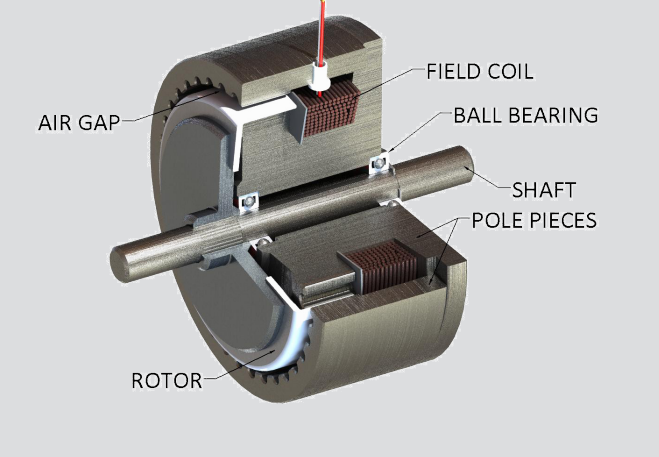

Brake Design

Researched and documented findings on the best way to apply a controlled torque on a rotating shaft.

Learned about Hysteresis brakes, and spec’d one suitable to test all our powertrains.

Educated the team about this type of brake, helping them understand why it is superior to the previously proposed solution.

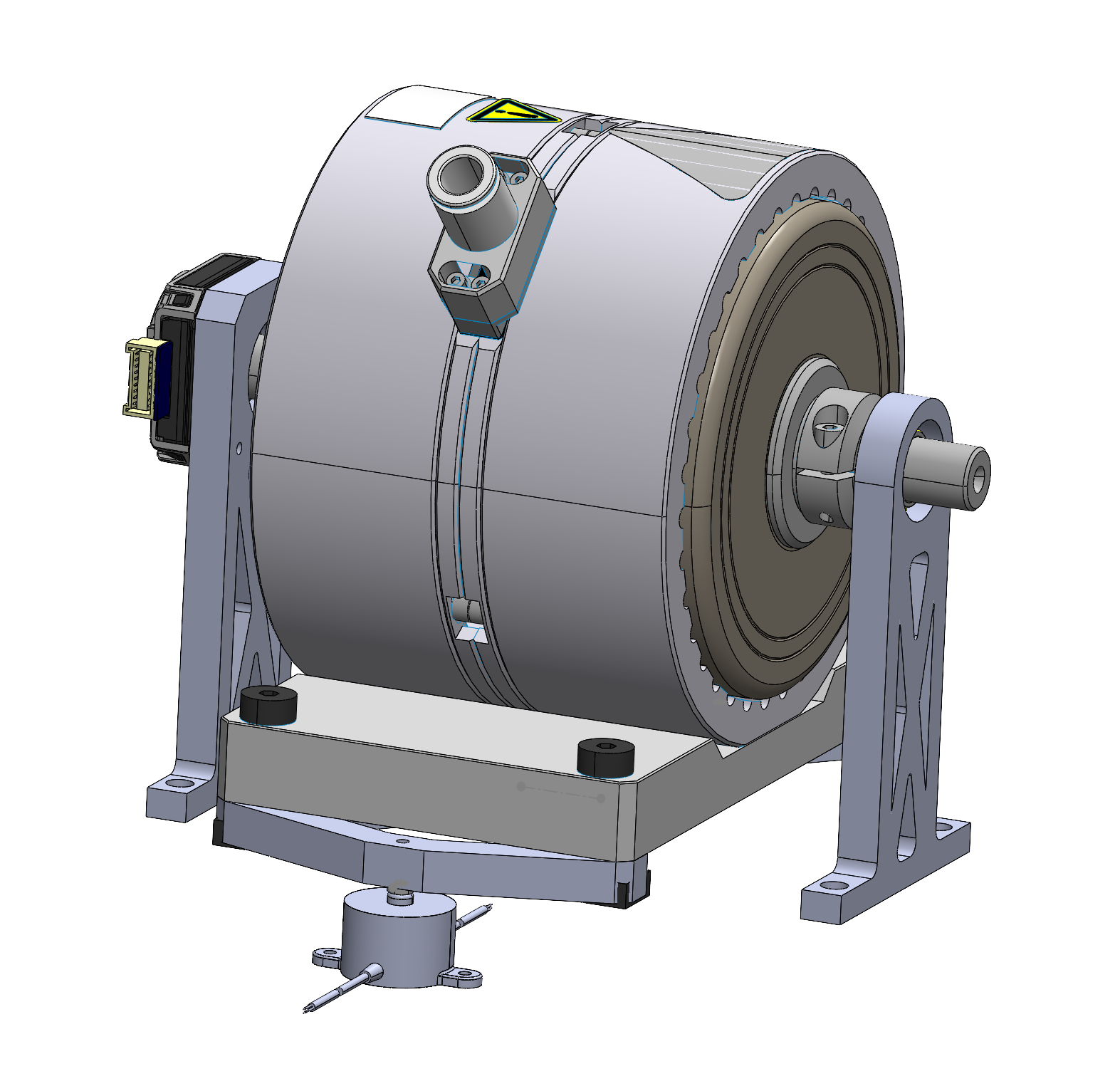

Mounts and Accessories Design

Reduced cost by $6,000 by developing a cost-efficient way of measuring the torque applied by the dyno.

Designed a mechanism able to measure the torque applied on the shaft by measuring the reaction force of the dyno on the table.

Spec’d bearings, force sensors, and RPM sensors that minimize noise in the data, and allow us to test all motors or powertrains.

Final Product

Completed the design of a dyno able to stress test and determine the efficiency of our motors and powertrains at any load or speed combination.

Combined with the Simulations, the team can now simulate an entire competition run on the test stand and determine at what point the vehicle is wasting most of its energy.