Objective

Redesign the powertrain to consume less current, allowing the electrical division to develop a more efficient motor controller.

Determining Motor Specifications

Used track data and current car specifications to determine the minimum power required to complete a lap on time.

Demonstrated that the previous motor was 4x more powerful than what was required.

The 1 KW Koford motor that we now use is 10% more efficient than the previous motor and draws 3x less current.

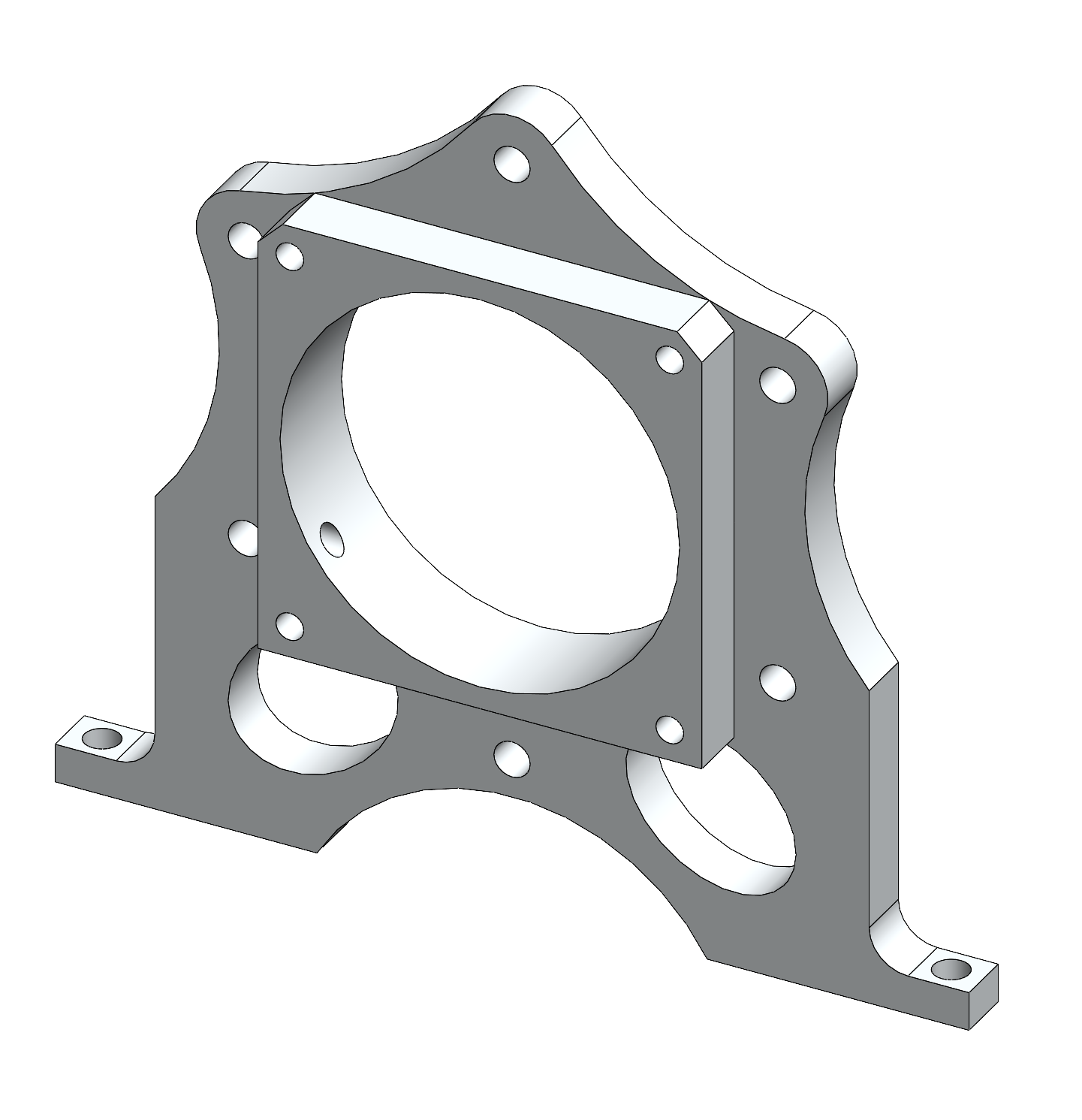

Mount Design

Reduced the powertrain weight by 800g (1.7lb) by designing a gear-motor adapter that functions as a mount for the motor and gearbox.

Increased powertrain efficiency by using the gear-motor mount as an adapter plate allowing us to directly fix the gearbox shaft onto the motor shaft.

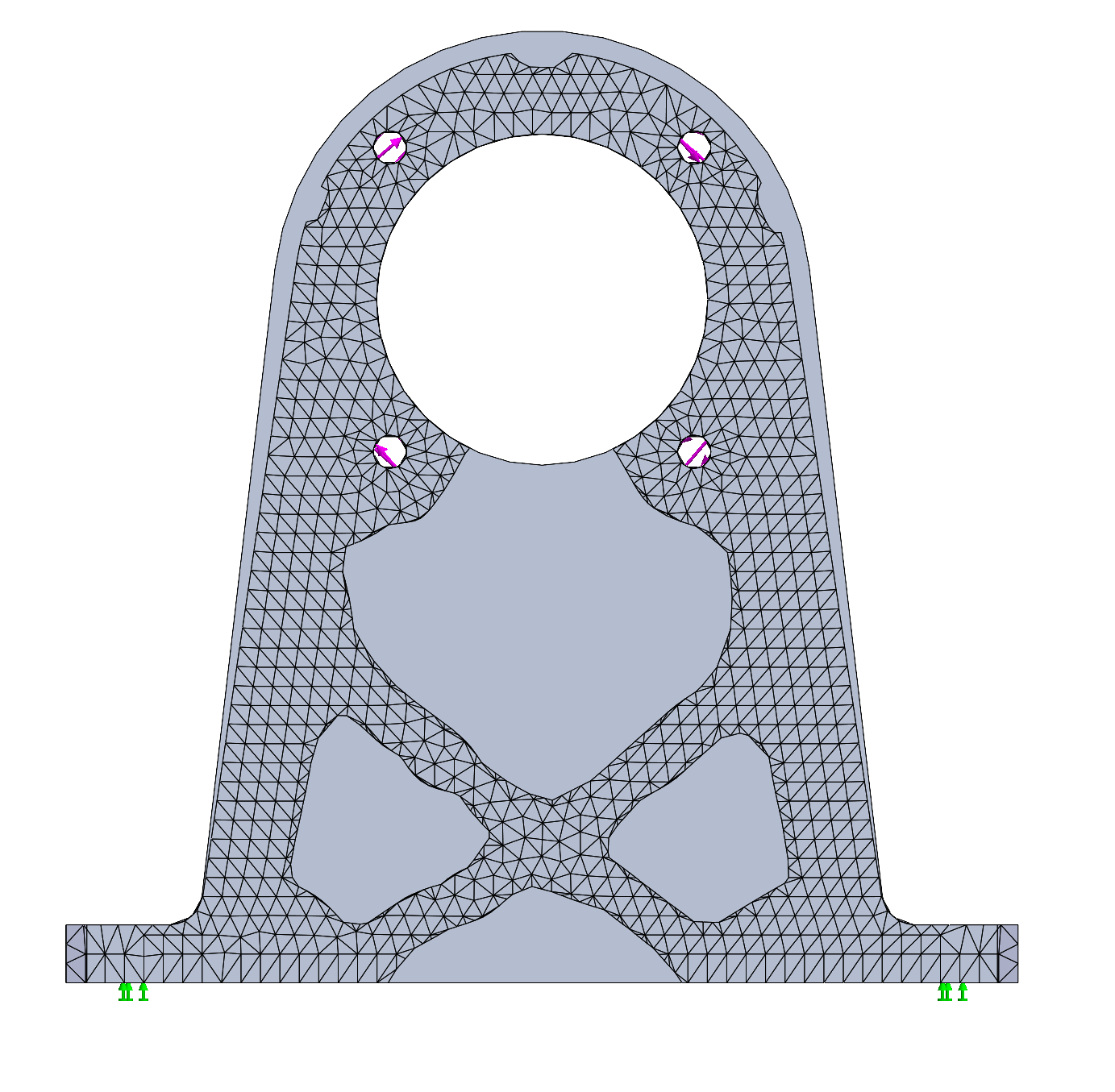

Learned how to use topology optimization to design 3 reliable, lightweight mounts.

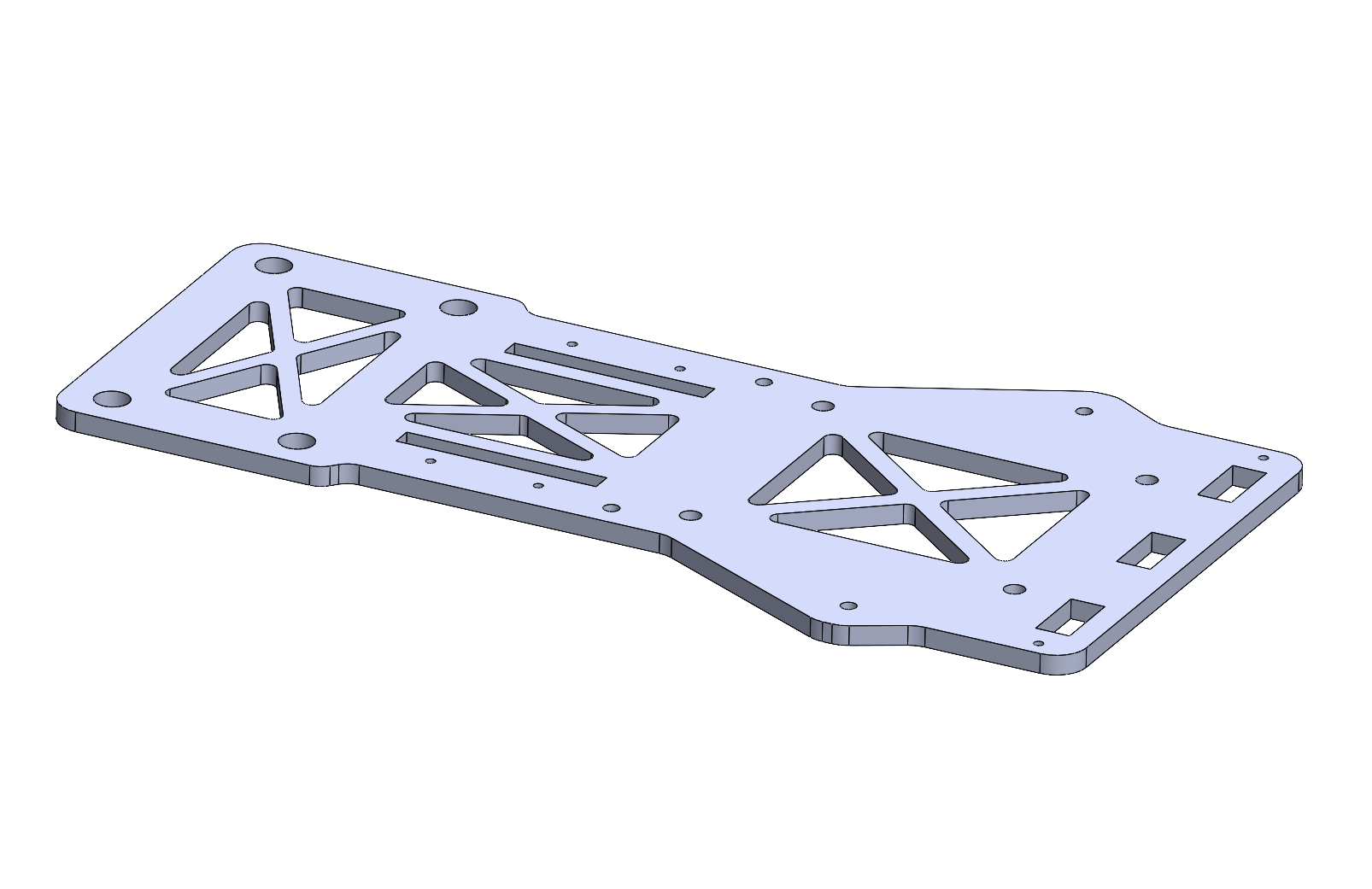

Manufacturing

Used the milling machine to accurately position the holes, ensuring optimum shaft alignment.

Used the waterjet where possible to finish all 3 parts in under 1 month.

Final Product

Designed a new powertrain in 7 months, or half the time previously used.

Decreased the number of components required from 7 to 4.

Reduced the powertrain weight by 1.5Kg (3.3 lb).

Increased efficiency by 30%.